Cleaning & Disinfection, Knowledge Base

“Lint-Free” Wipes: Available Only Through Your Fairy Godmother

Web searches for “Lint Free Wipes” provide some interesting information. A Google search returns 82,300 hits. A search of “lint-free” on the American Society for Testing Materials (ASTM) site returns 265 hits, and a search of “lint-free” on the United States Pharmacopeia (USP) site returns 737 hits. Of these, three are contained in the <797> document on pharmaceutical compounding-sterile preparations. Surely, with that many references and with citations from both the ASTM and the USP, “lint-free” wipers must be real.

Actually, not. There is no such item as a “lint-free” wiper. “Lint-free” is a misnomer. How can that be?

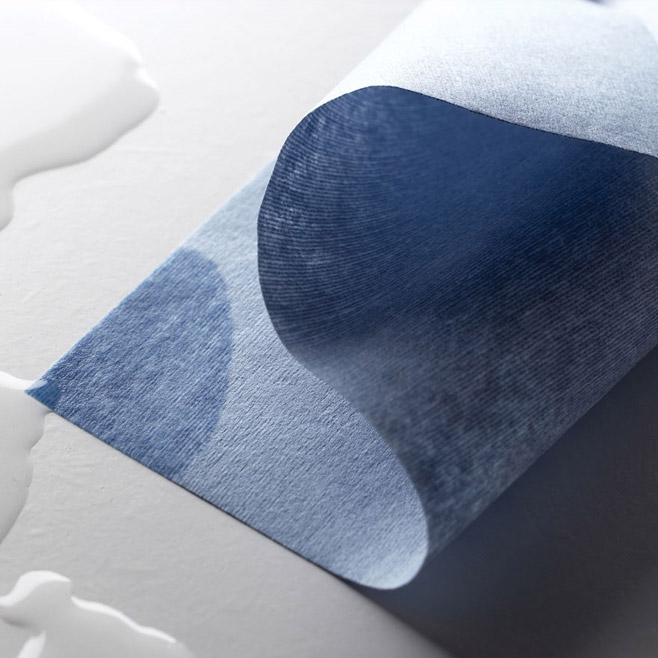

Lint” is a catch-all term referring to the short, fine fibers that separate from the surface of cloth or yarn. Lint is a consequence of using fabrics to make wipers, whether those fabrics are man-made polyester or nylon, natural materials such as cotton or cellulose, or blends such as hydro-entangled polyester-cellulose. Use a fabric, and you can’t escape the presence of accompanying lint. So, whence lint-free?

Dry Testing

When specialty wipers were first developed for use in cleanrooms, measurement techniques were not well developed. In the early 1980’s, air particle measurement techniques were developed for testing wipers – so called “dry testing.” These measurements, which involved flexing wipers mechanically, showed few releasable particles and fibers emerging from the wipers. Similarly, some wipers left behind few if any visible particles or fibers on the wiped surface. Hence the term “lint-free.”

Wet Testing

In the mid 1980’s, all of that changed when wipers were immersed in water or a dilute surfactant solution and gently agitated for a short period of time – so called “wet testing.” When the solution (that had been in contact with the wipers) was passed through liquid particle measurement instruments or alternatively passed through membrane filters, and the filters examined microscopically, suddenly significant numbers of particles and fibers were visible. The particles and fibers that adhered to the wiper when it was dry were released to the liquid and became available for detection and quantitation. It became clear that even the highest quality cleanroom wiper contained some amount of particles and fibers, the components of lint. It is interesting to note that the most recent publication (2004) on wiper testing issued by the Institute for Environmental Science and Technology includes wet testing, but not dry testing. Refer to IEST-RP- CC004.3, Sections 6.1.3 and 6.2.2.2 for examples of acceptable wet testing procedures. Wet testing “sees” the particles and fibers that dry testing misses and also provides greater measurement reproducibility.

Unfortunately, the “lint-free” adjective was never scrubbed from the cleanroom lexicon. Beware of wipers that are marketed as “lint-free”, because that attribute doesn’t exist.

Editor’s Note: The fairy godmother reports that her supply of “lint-free” wipers mysteriously disappeared with the advent of wet testing.

HAVE AN IDEA FOR CONTENT?

We are always looking for ideas and topics to write about.

Contact Us