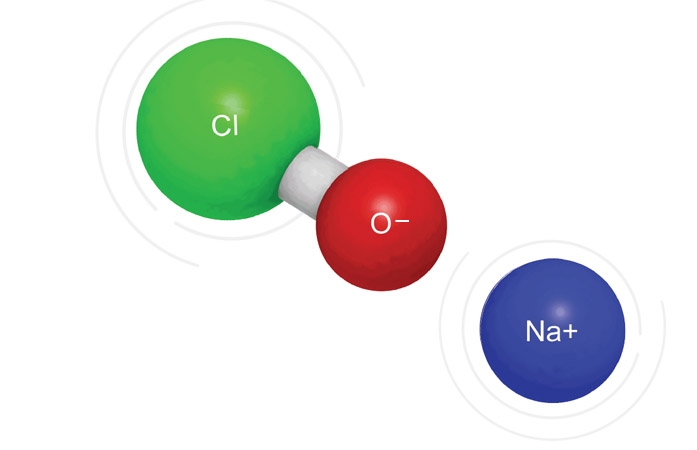

A previous article in this series discussed disinfection of surfaces with hydrogen peroxide. We turn our attention now to bleach as another very effective treatment agent. Most people understand that ordinary household bleach – a 5.5% solution of sodium hypochlorite (NaOCl) in water – is a strong disinfecting agent. In neutral or slightly acidic solutions the active [Read More…]

Category Archives: Cleaning & Disinfection

The EasyClean® 360 is the most efficient way to clean a laminar flow hood. It’s unique triangular shaped head allows it to clean the difficult tight corners in the hood. The tool is delivered with two handles, a 14” (35cm) and 24” (61cm). There is also another ordering option for a telescoping handle that will extend from 35 [Read More…]

Faced with the problem of removing small bits of contamination in the cleanroom, you would probably have to invent the swab if it didn’t already exist. You would soon find that this little “wiper on a stick” would also prove invaluable in cleaning delicate mechanisms, in precision surface cleaning and in removing residues in hard-to-reach [Read More…]

ISO Class 5 – Primary Engineering Controls (PECs) LAFWs – BSCs – CAIs – CACIs At the beginning of the each shift Before each batch No longer that 30 minutes after previous disinfection (during ongoing compounding) After spills When a surface contaminate is known or suspected Clean area after surface sampling (i.e. Contact Rodac Agar [Read More…]

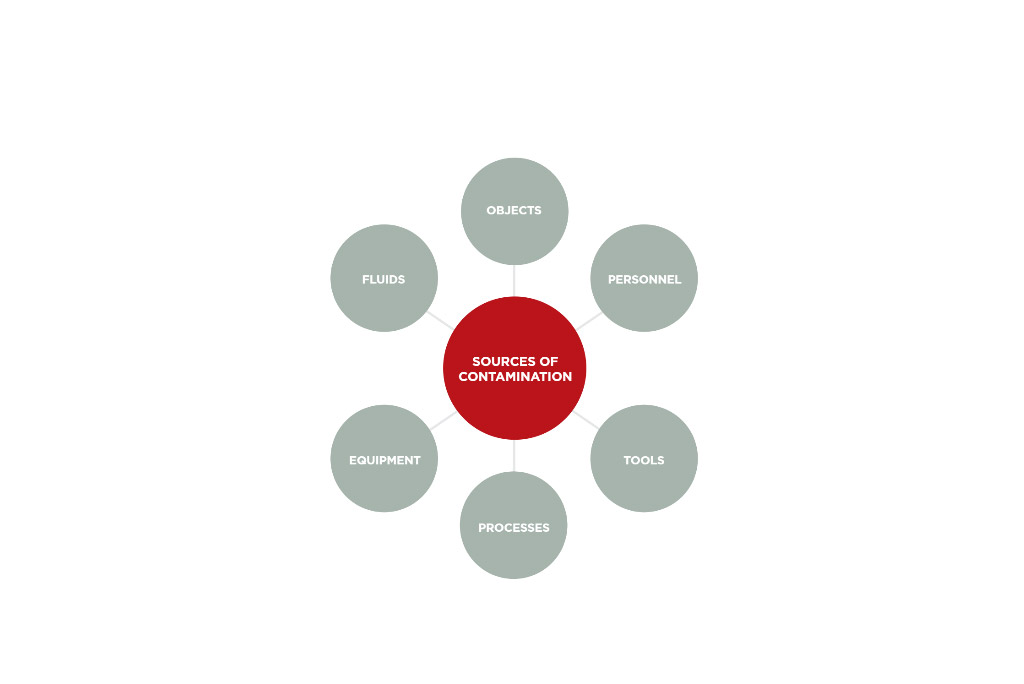

SOURCES OF CLEANROOM CONTAMINATION What Are The Most Common Sources Of Contamination In A Cleanroom? People & Personnel Objects Fluids Tools Equipment Processes What Are The Most Common Types Of Cleanroom Contamination? Skin Particles Fibers Dust Grease Bacteria Viruses Metals Fungi NVRS (Non-volatile Residues) Ions Films DID YOU KNOW? Using Cheap Or Substandard Cleanroom Wipes [Read More…]

Q: What is the Best Food Contact Surface Wipe? A: The best food contact compliant surface wipe must be tested by a third party lab for compliance with FDA 21 CFR regulations. The following Berkshire wipes have been tested and are compliant, written test results can be provided upon request. Pro-Wipe 750 Pro-Wipe 880 [Read More…]

Pro-Wipe® OS This industrial wipe from Berkshire is engineered specifically to absorb and retain oil. The wipe complies with FDA CRF 177.1520 for food contact surface applications. It is an excellent choice in gel cap manufacturing for drying and polishing or any other application where oil needs to be removed.

Let’s start with a quick story titled “The Mystery of the Talking Plant”. On a dry, wintry day a son calls out to Mom. MOM!!! The plant in the living room is talking to me, really! “What?” “No, seriously Mom. I had just finished vacuuming and the plant next to me started making a buzzing [Read More…]

Although it may seem like longer, it was just two short months ago that we welcomed in a new year, one full of promise for exciting developments in the contamination control industry. And it’s off to a flying start. Already in February, as we were still reeling from the issues with Tri-Coast Pharmacy(1), came not [Read More…]

In this post we will continue with the next part of our series Cleaning A Contaminated Personnel’s Behavior Decontamination Tools for Quality Managers, to see how we can eliminate the cause of nonconformity and also prevent the occurrence of the same undesirable situation in the future. You can find Part 1 of the series here. Fill out [Read More…]