Berkshire Products, Knowledge Base

What is the Difference Between Open and Closed Cell Swabs?

Cleanroom Swabs 101 – Closed Cell Vs. Open Cell Polyurethane Foam Sock Tip Swabs

1. How are sock tip polyurethane foam swabs constructed?

Sock tips are made by sandwiching the swab handle between multiple layers of thermoplastic head material. The head material is completely sealed and bonded to the handle with heat and pressure. No contaminating adhesives, silicone, amides, and DOP are used in the manufacturing of Berkshire’s sock tip swabs.

2. What is the difference between a closed cell and open cell sock tipped polyurethane foam cleanroom swab?

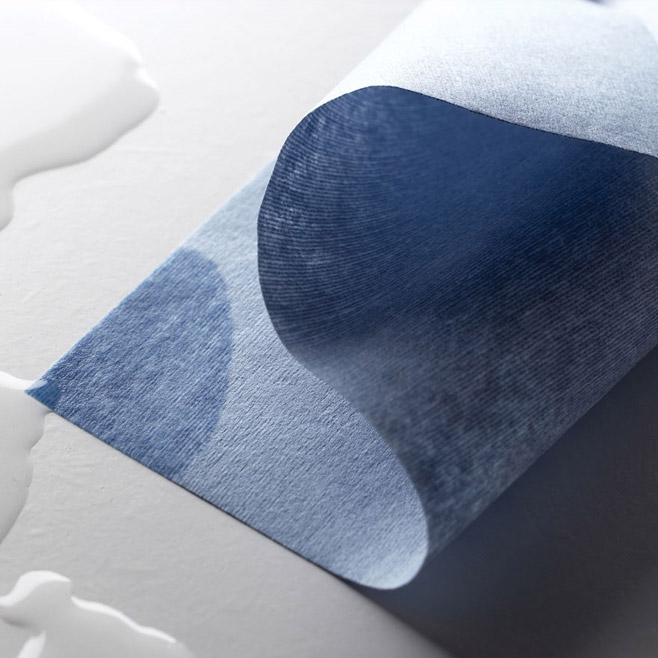

Closed cell (non-reticulated) foams are completely sealed with cell windows intact. Closed cell foams generally exhibit higher density, greater durability and reduced absorption versus open cell foams. The foam is laundered and packaged in an ISO Class 4 (Class 10) Cleanroom.

Open cell (reticulated) foams are structures in which the cell windows have been removed by thermal or chemical means. This process results in a structure that has excellent liquid retention and particle entrapment capability. The foam is laundered and packaged in an ISO Class 4 (Class 10) Cleanroom.

3. What is the main difference between open cell and closed cell polyurethane swabs as it relates to specific applications?

While they are both excellent for chemical/solvent resistance (see our solvent compatibility chart), the open cell has better liquid retention and is more absorbent with better particle entrapment capability. The closed cell is preferred for rigorous/scrubbing applications, removing challenging excess material and applying lubricants and other liquids.

While they are both excellent for chemical/solvent resistance (see our solvent compatibility chart)!

HAVE AN IDEA FOR CONTENT?

We are always looking for ideas and topics to write about.

Contact Us