Berkshire Products, Knowledge Base

Important Wiping Techniques for Really Effective Cleaning

Throughout this series, we have addressed several things related to pre-wetted wipers, including the convenience and consistency of presaturated wipers, how to unlock the best wiper for your cleanroom, and the powerful wetting solution of isopropyl alcohol (IPA). So, now that we’ve explored some foundation elements related to pre-wetted wipers, what techniques can we apply to ensure effective cleaning? That’s what we’ll explore in this week’s article.

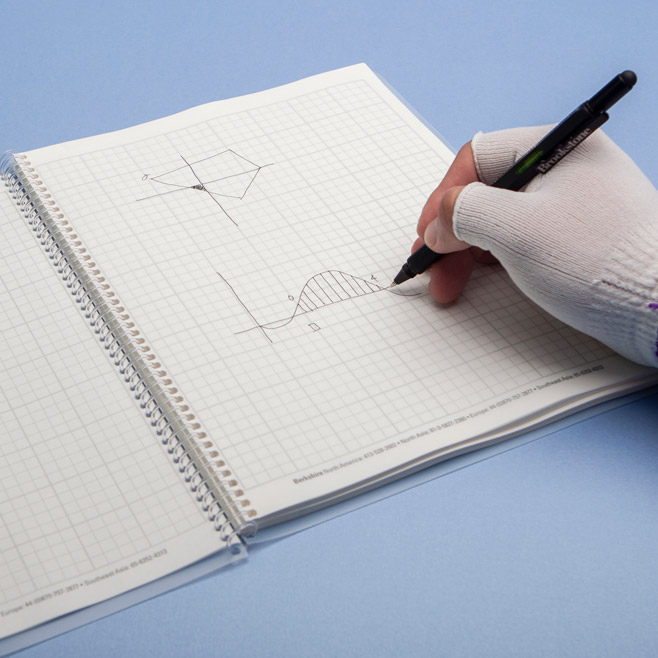

Frequently, cleanroom protocol requires that you wipe surfaces at the end of a shift and then again at the beginning of a new one. The best practice is to use a pre-wetted wiper to clean the gloves before cleaning any surface, then discard this wiper. This protocol eliminates the possibility of glove contaminants being transferred to the pre-wetted wiper then to the surface that you need to clean.

Imagine for a moment that you’ve entered the cleanroom, and you have your 9″ x 9″ pre-wetted wiper; now what? Do you use it as is, or is there a more effective way to use the entire surface area of the wiper? It so happens that there is a better way to use it: quarter-folding.

Quarter-folding a 9″ x 9″ pre-wetted wiper will provide up to 8 clean wiper surfaces. Linear wiping (rather than circular wiping) will optimally remove surface contaminants. Why linear wiping instead of circular wiping? It’s because experience has shown that circular wiping can spread contamination over the wiped surface, thereby minimizing contaminant removal.

It’s also essential to expose a new wiper surface after each linear wiping stroke. If there are traces of liquid left on the surface after wiping, allow them to air dry. The strong downward laminar flow from the HEPA filters in the ceiling will quickly evaporate any liquid traces. Typically, most cleanroom surfaces appear to be clean. However, removing submicron contaminants (invisible to the naked eye) may not make the surface appear to be any cleaner after wiping.

Now, what if the surface you need to clean is visibly soiled? Well, that requires a more rigorous wiping approach. First, use pre-wetted wipers with linear strokes as described above. Discard the used wipers more frequently to avoid re-contaminating the surface. Continue wiping to the absence of visible soil on the surface until the “final” wiper shows no soil trace. Discard that “final wiper,” then take a new pre-wetted wiper and proceed as described above, wiping a visibly clean surface.

The benefits of using pre-wetted wipers in this exercise are significant. Why? Because cleanroom wiping using dry wipers and a squirt bottle of cleaning liquid (typically an IPA solution) is more challenging for several reasons.

Often squirt bottles are not conveniently available or are empty. Also, there’s the challenge of dispensing the optimum amount of cleaning liquid. For example, too little liquid will be available to effectively break the bonding forces between particles and surfaces, and contaminant removal will be compromised. Conversely, by dispensing too much liquid onto the wiper, the liquid will merely spread across the surface with little contaminant removal. With a pre-wetted wiper, there is no guesswork. Since it’s already saturated, you can begin cleaning without the need for extra steps; thereby improving your cleaning efficiency.

We hope we’ve helped share some insight to improve your wiping techniques or give you some good guidelines to follow if you are new to wiping down surfaces in a cleanroom.

Of course, we’re always happy to answer your questions regarding your cleanroom contamination needs, so feel free to reach out to our trained specialists for more information.

We hope you’ll join us next week when we talk about an essential aspect of pre-wetted wipers: their packaging.

HAVE AN IDEA FOR CONTENT?

We are always looking for ideas and topics to write about.

Contact Us