AAMI is the Association for the Advancement of Medical Instrumentation. Berkshire’s line of Gamma Wipe® cleanroom wipes are gamma irradiated and validated sterile to a 10-6 Sterility Assurance Level (SAL) per AAMI guidelines. Did you know? – The International Organization for Standardization (ISO) defines Sterility Assurance Level (SAL) as the “probability of a single microorganism occurring on an [Read More…]

Category Archives: Aseptic Cleaning

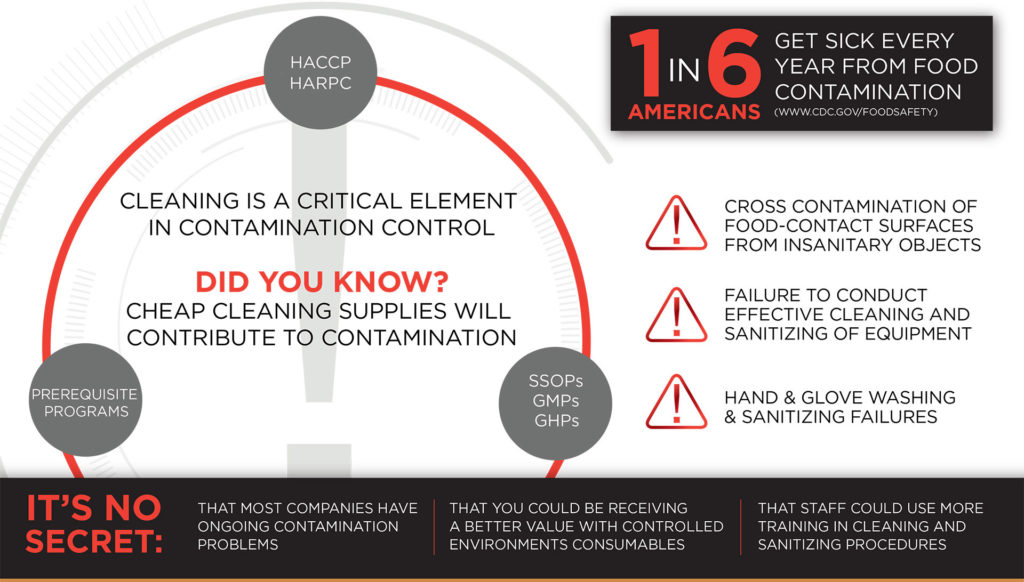

Although it may seem like longer, it was just two short months ago that we welcomed in a new year, one full of promise for exciting developments in the contamination control industry. And it’s off to a flying start. Already in February, as we were still reeling from the issues with Tri-Coast Pharmacy(1), came not [Read More…]

Is the validation process the same for sterile presaturated vs. sterile dry wipers? Yes, the validation process is the same for presaturated vs. dry as they both follow ANSI/AAMI/ISO 11137, Sterilization of Health Care Products. The product is saturated, packaging is sealed and then the cases are sent to be irradiated. The cases are irradiated wet. [Read More…]

Gamma Irradiated refers to a product that has been irradiated at some predetermined dose which is felt to kill the bioburden. Sterility testing is usually not performed nor quarterly audits for continued validation. The Sterility Assurance Level (SAL) cannot be predicted. A higher dose of radiation may be delivered to the product than may not [Read More…]

In contamination control, there are generally two types of contamination problems: complex problems that even those who are dedicated to cleaning out sometimes miss, and outright negligence. Sometimes, an issue as simple as not knowing the proper contamination control procedures can lead to contamination that gets the FDA on you. That was the case recently [Read More…]

Sterile compounding in a pharmacy involves customization of medication mixtures in a minimal contamination environment. Safeguarding against unwelcomed contamination is a tall order because many of the small contaminants are invisible to the eye and hidden as microorganisms. The robust standards established by the United States Pharmacopeia (USP) Chapter <797> for cleaning and disinfecting the [Read More…]

he final step in the manufacture of sterile wipers (either dry or pre-wetted) is gamma irradiation to destroy all viable organisms that may be present on the wipers or on associated packaging. A source of confusion that often arises is how best to introduce packages of sterile wipers into the sterile suite. Most users understand [Read More…]

Let’s focus on one of the most challenging cleaning requirements for the pharmaceutical industry – cleaning equipment used to manufacture injectable materials – so called “parenteral drugs”. These materials must be made in environments that are absolutely clean and sterile, because there is no opportunity for the drugs to be sterilized after packaging – i.e. [Read More…]

IF YOU ARE MANUFACTURING in an aseptic environment, it’s important for your cleanroom supplies to be sterilized with a validated process. This whitepaper, written by Lynn Stanard, Berkshire’s Senior Quality Manager, will help you understand the sterilization methods used by consumables suppliers and what to look for when procuring supplies Sterile Cleanroom Management This whitepaper provides [Read More…]